Sirris: Additive manufacturing adds value through innovation

Text: Maya Witters | Photos: Sirris

S irris has been in the business of additive manufacturing, or 3D-printing as it is more commonly known, for 30 years. As the first organisation in Belgium to invest in a 3D printer back in the day, it has since built a considerable body of expertise, which it uses to streamline production processes for its clients. “The potential is limitless.”

Additive manufacturing refers to the process of stacking hundreds of thin, precise layers of material to build a product. “It’s the reverse of traditional sculpting: rather than remove outer layers of material, we build an object layer by layer,” explains Sirris additive manufacturing team leader Benjamin Denayer. “This is not a new idea in itself, but many of the modern applications are fairly new and the technique is still finding its way into manufacturing processes.”

Sirris helps flight simulator manufacturer Venyo recreate missing parts through 3D-printing.

Complex parts, simple processes

As a non-profit research and technology centre, Sirris mostly acts as an R&D partner for companies looking to innovate. “Essentially, we guide our clients through the process of introducing new technologies,” Denayer attests. “We help them identify opportunities for 3D-printing, carry out feasibility research, and assist with the production design and integration.”

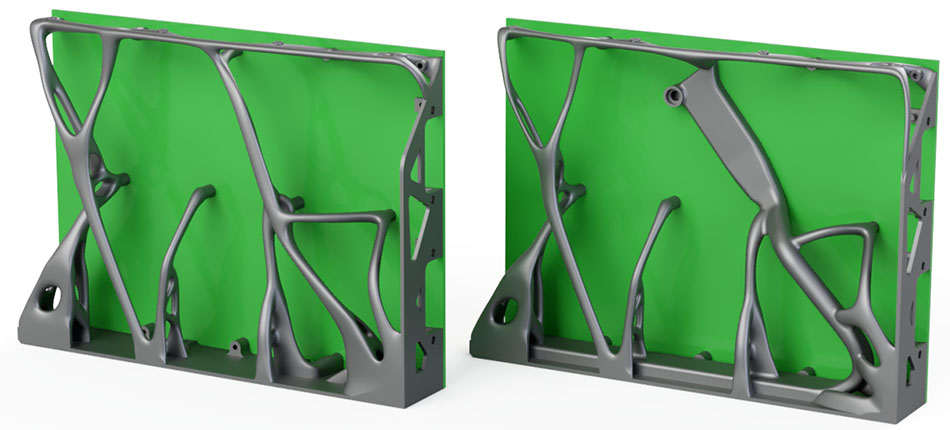

Introducing 3D-printing methods into the manufacturing process can optimise production by reducing the number of parts, as Denayer explains. “Because 3D-printing allows for the creation of much more complex shapes and structures in one part, the manufacturing process is streamlined by lowering the number of required assemblies.”

Helping the Belgian industries innovate

Many of Sirris’ clients are in the space and air transport industries. “We recently collaborated with Thales Alenia Space Belgium to investigate how a new design for its PCB support structures could increase efficiency and help abduct heat. And we worked with Venyo, a company that uses decommissioned cockpits to create flight simulators, to recreate missing parts through additive manufacturing.”

“But other industries can also benefit hugely from our services,” concludes Denayer. “There are plenty of gains to be made in the medical field, machine manufacturing and the process industry. Each year, we answer around 3,000 enquiries from 1,500 companies in Belgium – most of them SMEs – with our extensive expertise.”

Sirris helped Thales Alenia Space Belgium redesign PCB carriers for maximum efficiency thorugh additive manufacturing.

For more information, visit: www.sirris.be

Subscribe to Our Newsletter

Receive our monthly newsletter by email