GOM

The future of measuring

TEXT: ARNE ADRIAENSSENS | PHOTOS © GOM

The era of tactile measurement is far behind us. Companies looking for a future proof measuring system, opt for the reliability of 3D-scan technology. With the aid of two cameras and their proper software, GOM is globally renowned as a most reliable and innovative partner for measuring technology.

Industrial manufacturing is an exact science. Any discrepancy or tiny flaw can disrupt an entire production line or can result in an inferior product rolling off the assembly line. Therefore, data is king in the production industry. GOM is the ideal partner to help you gather just that. “As a firm, we specialise in 3D-scanning and testing equipment,” Wim Cuypers, sales manager for the Benelux branch, explains. “We provide state-of-the-art software and hardware, which we both create ourselves, and which therefore cooperate seamlessly.”

Digital twin

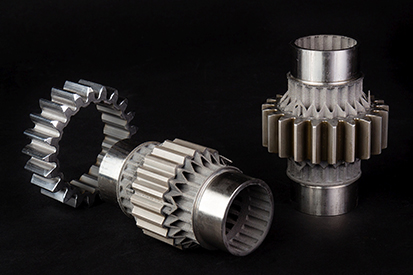

Implementing 3D-scanning in your company, rather than traditional tactile measuring, has many advantages. While measuring up free forms and complex geometries, for example, the old method is inadequate since it only measures one point at a time. A 3D-scan, on the other hand, registers all the points of an object in no time and creates a digital twin of the artefact on which you can perform your calculations and measuring. Afterwards, you can save the digital copy and its data on your computer as irrefutable evidence. If you later on decide to perform some additional measuring, your scan will be there at your service, even if the original physical product has shrunk or set out a few millimetres because of the temperature or humidity.

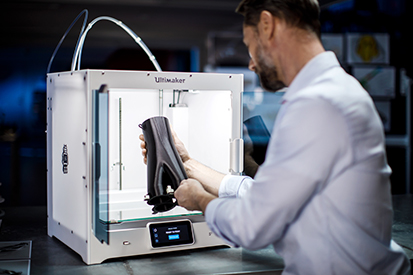

As products become more complex by the day, the demand for 3D-scanners has increased significantly. “Additive manufacturing allows companies to create very complex shapes. To showcase the functionality of those printed parts, clients can not only use our 3D-scanners for checking its dimensional quality but also our 3D-testing equipment to evaluate strength, heat resistance and other crucial parameters.”

Plug-and-play

By setting high standards for themselves, GOM has increased the accuracy that their products can achieve astronomically. Many factors can influence how exact your digital twin turns out. Reliable data quality is very important. Vibrations of a truck, passing on the street can result in irregularities in the data. “Not only do we use the best cameras, but we also use two of them per scanner,” Cuypers states. “This way, the sensor monitors itself, allowing it to have the most reliable data quality. As an extra guarantee, it also checks the calibration itself.”

“It is true that implementing customised systems like these can cost you much money, effort and time. To avoid this, we also offer multiple standardised models, or Scanboxes, which can be introduced effortlessly. They come in different sizes, for a variety of uses and sectors, and in gradations, from easily controllable to expert level. Either way, they are plug-and-play devices that are operational in no-time.” This opens doors for smaller companies for whom the cost of the machines, the start-up or the operator was too high till now. Scanning technology is no longer a privilege for the biggest in business.

Industry 4.0

While gazing into the future, Cuypers still sees many interesting challenges for his innovative company. “The industry is on the brink of entering Industry 4.0 and we are ready for it. We are designing methods to interlink our products to an internal network and make sure our software is future proof. We have also introduced the GOM CT, computer tomography to scan underneath the surface of an object as well, and also capture its internal channels and parts. Progression is important to us, but we also want to keep offering simpler solutions for companies with tighter budgets or less complex needs. Our software can already read CAD-files, yet we make sure it remains compatible with older 2D- and 3D-files as well. A revolution to Industry 4.0 happens on the assembly lines of the production companies. But, when they decide to join the movement, we are more than happy to help and facilitate them wherever we can.”

Subscribe to Our Newsletter

Receive our monthly newsletter by email